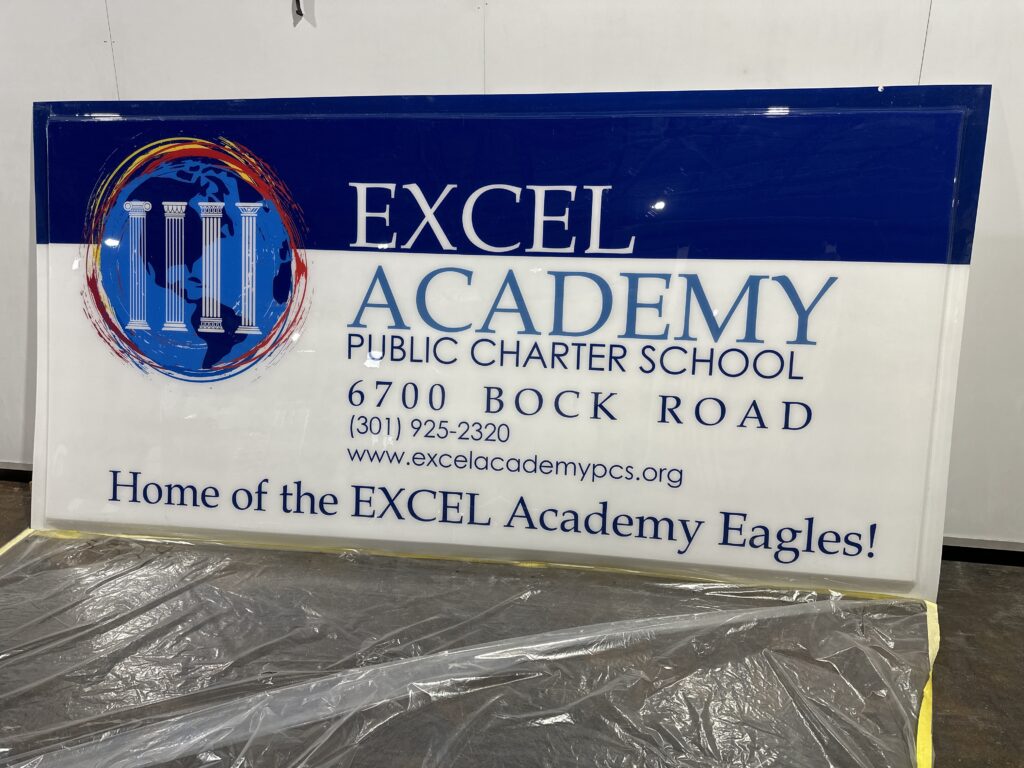

Formed Faces

Vacuum Forming

We have two unique in-house engineered high production vacuum forming ovens that are capable of producing up to 86 formed sign faces per day compared to any other competitor’s oven that makes 20 faces/day. This makes Wholesale Sign Superstore “hurricane-proof”, and allows to meet any demand for sign faces in the Southeastern United States. We can make a sign face with High Impact Modified Acrylic as large as 8′ x 20′ in one piece.

Materials

We form exclusively with Plascolite High Impact Modified Acrylic. The most evident effect of the elements on a rigid plastic sign face is yellowing. This is particularly true of plastic sign faces with white backgrounds. For long-term clarity (8-10 years), the acrylics are often recommended because they will not significantly alter the color of the underlying sign graphics during that time period. The materials are impact resistant, withstand high wind, certain hurricanes and blizzards.

Acrysteel© vs. polycarbonate sheet comparison:

| Acrysteel© (X-15) | Polycarbonate | |

| IMPACT STRENGTH | HIGH | HIGH |

| UNBREAKABLE | NO | NO |

| COST MORE | NO | YES |

| BETTER WEATHERABILITY | YES | NO |

| BETTER: GLOSS | YES | NO |

| BETTER: CLARITY | YES | NO |

| BETTER: COLOR | YES | NO |

| HIGHER WIND LOADS WHEN INSTALLED CORRECTLY | YES | YES |

| LASTS LONGER | YES | YELLOWS |

Types of plastic sign faces

- Flat faces

- Pan Faces

- Pan Embossed/Debossed Faces

- Custom Pan Faces

Clear embossed face Embossed Painted Face

Flat faces

Applying vinyl to flat acrylic sheets is very popular. This is a very useful application in many cases. But, some caution should be used when dealing in this area. It is not recommend using a flat face when the LEDs in the face will be closer than 4″ from the sign face. With the LEDs being too close to the face you might see the image of the bulbs, plus the heat factor can cause problems to the face. It is also not recommend using flat faces in cases where the dimensions are greater than 32 square feet. A flat face loses its strength as it becomes larger and runs the risk of being blown out of the cabinet during strong winds, hurricanes, tornadoes.

Pan Faces

Pan faces are an excellent alternative to flat faces. The face is vacuum formed to a depth of 1.5 “. This gives more than just a decorative appearance to the face, it adds strength and durability. You may order white pan faces and apply your own translucent vinyl or you may wish to have us back spray the artwork in translucent paints so it will come to you completely finished.

White Pan Face White Pan Face with

radius corners

White Pan Face with

radius corners Applying Vinyl on

White Pan Face

Pan Embossed/Debossed Faces

Pan embossed faces are similar to pan faces, but some or all of the copy may be raised. Dies are placed on top of the mold to create this effect. Embossed pans can cosmetically improve the appearance of the face as well as adding additional strength.

Hand painted embossed face “Bagel Man”.

Custom Pan Faces

Creativity pays. Be creative. Signs do not have to be built in a rectangular shape. Custom signs sell. The price is always higher due to custom molds, but sometimes creative artwork wins out over a price. Do a sketch of the artwork you have in mind and ask your sign company (if you are a sign owner, ask your sign company. If you are a sign company, then ask us – your wholesaler) to quote the project. Your account representative may have some other ideas to develop into your sketch to make the project feasible and more affordable.

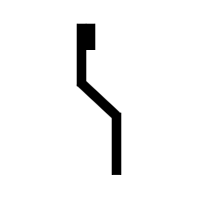

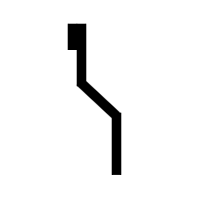

Pan Face Hangrails

Depending on the extrusion, formed faces can be manufactured in one of 2 hangrails if requested:

| Outside | Inside | |

|  |